Wax jewelry it is! As children we were fascinated by the human ability to transform nature in order to satisfy our needs. My eyes opened wide before the magnificence of the buildings, the magic of the means of transport and in general I had a tendency to admire every tentacle of human civilization.

So, in the insatiable struggle to satisfy my curiosity, one day I asked my mother what was this metal object that hugs her finger. Then she answered me with a pervasive smile that it is the symbol of love. And my mother began to marry the incomprehensible emotions with the science of inanimate materials. This science is called Engineering.

So in this article, we will refer to the industrial process of producing objects that ignite human passion. I am referring, of course, to jewelry.

Wax Jewelry – Why should I be interested in Engineering?

At first it is easy to understand that the practical results of this particular science are all around us. Let us first approach Engineering from a philosophical perspective. The way in which we perceive the reality around us varies and if one looks for the cause, it lies in the different cognitive level of each person. Take a moment and look at the area around you. Do you have any idea what it takes to make a table, a car door or a souvenir from Rome? Allow me to be your assistant in this mysterious, complex and fascinating place of awareness and knowledge.

What is Manufacturing Technology?

Technology is the set of achievements (inventions, processes, methods) resulting from the application of scientific or technical knowledge for practical purposes. Kazantzakis once said that “the purest and most sacred form of theory is practice”.

Industrial production is the set of processes aimed at converting raw materials into products. At the Kosmogonia jewelry school you will gain unique knowledge at all levels.

What is Casting?

Casting is one of the most well-known production technologies. More specifically, casting is mass-conserving machining. The molten metal is poured into a suitable cavity, the so-called mould, where it solidifies. With this method we can mainly produce products made of ferrous metals (cast iron, steel) or non-ferrous metals (aluminium, brass, copper).

Mold geometry is crucial. In particular, it must withstand the forces of the molten metal while at the same time its configuration must not impede the flow of the melt. The mold must allow the removal of both air and gases produced during the reaction of the hot metal with the type. In addition, the geometry of the mold must provide for the phenomenon of contraction of the casting during its solidification.

So having explained the basic mechanical concepts, it is time to describe the type of casting that is capable of producing products with flawless surface quality and unparalleled dimensional accuracy. The name of this method is “Lost Wax Casting”. The method name describes the backbone of the procedure. The method is known from Ancient Egypt in 1500 BC where it was used to make sculptures and bronze objects. It is no exaggeration to claim that lost wax casting is as old as the earliest traces of civilization. In the handmade jewelry courses you will enter the magical world of manufacturing.

This method in our time with the help of digital design and 3D design holds the reins of jewelry production on an industrial level. Precisely because the world around us is driven by high competition and demand, as well as the intense pace of fashion, the effort of handmade jewelry to respond in time to new challenges is constantly waning and fading.

Enough with the theories though… Let’s try to understand the way the Lost Wax method works.

The Lost Candle Wax in 9 steps

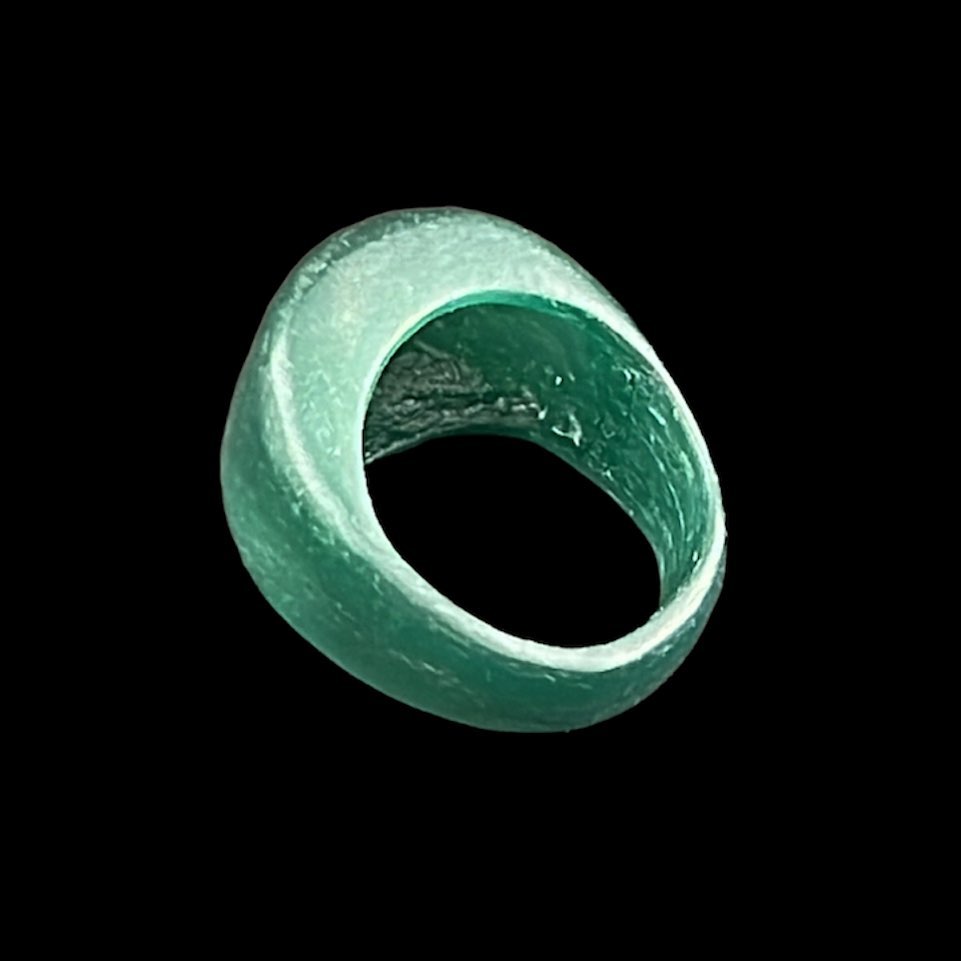

- Create the desired design in wax before making a mold around it.

- Make your mold using cast which supports the mold, and silicon with its high refractoriness characteristic. Add water until the coating has the consistency of heavy cream.

- Fix this cream of ceramic material.

- Burn the candle while placing a small container underneath to collect the melted and fallen wax. The easiest way to melt wax is in a microwave or a regular oven.

- Select the metal alloy. Silver, copper, gold and platinum are widely used in a jewelry studio.

- Melt the alloy by heating it to the melting temperature.

- Pour the molten metal into the mold.

- After the metal has cooled (solidified), you can remove it from the mold.

- File and polish your solid metal jewelry. This step is all about the employee experience.

Book: Production Technology, Nikolaos Tsourveloudis

In summary, the Lost Wax method is an efficient process, able to keep up with the high standards of the market. For the importance of this particular method, one has to consider that it was born in 1500 BC. Today, however, this type of casting has been perfected with dazzling results. Check out the jewelry from the biggest fashion houses. Now you know how they are made.